Product Description

• All king combination nipples are 100% T316L stainless steel.

• Combination nipples are recommended for low-pressure discharge and suction service for compatible liquids. They are not for compressible products such as air or nitrogen on sizes 1¼" and above.

• King Combination Nipples are not recommended for steam.

• The working pressure may vary with the construction of the hose, the type of clamping system used and the application.

• In accordance with the Rubber Manufacturers Association bulletin for oil suction and discharge hose, a coupled length of hose in any size should be tested to 1½ times the working pressure and held for fifteen minutes without leaking or coupling movement. For additional information and detailed instruction on testing procedures, see the RMA handbook.

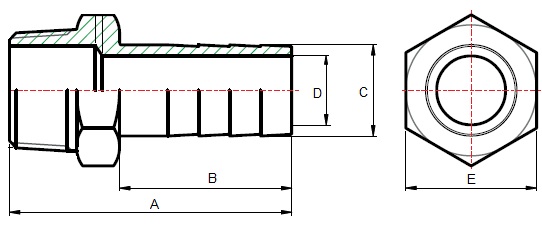

| Size (Tube OD) |

Part Number | Dimensions | ||||||

| A | B | C | D | E | ||||

| 1/4" | RST-025 | 1.575 | 0.930 | 0.354 | 0.276 | 0.630 | ||

| 3/8" | RST-0375 | 1.634 | 1.120 | 0.433 | 0.433 | 0.750 | ||

| 1/2" | RST-050 | 2.460 | 1.460 | 0.570 | 0.570 | 0.980 | ||

| 3/4" | RST-075 | 2.850 | 1.690 | 0.810 | 0.570 | 1.220 | ||

| 1 " | RST-100 | 3.230 | 1.970 | 1.050 | 0.790 | 1.500 | ||

| 1-1/4" | RST-125 | 3.150 | 2.090 | 1.340 | 1.060 | 1.810 | ||

| 1-1/2" | RST-150 | 3.640 | 2.200 | 1.590 | 1.300 | 2.050 | ||

| 2 " | RST-200 | 4.310 | 2.760 | 2.070 | 1.770 | 2.560 | ||

| 2-1/2" | RST-250 | 5.350 | 3.660 | 2.520 | 2.080 | 3.150 | ||

| 3 " | RST-300 | 5.790 | 3.820 | 3.070 | 2.760 | 3.780 | ||

| 4 " | RST400 | 6.220 | 4.090 | 4.090 | 3.540 | 4.720 | ||

Notes:

• All king combination nipples are 100% T316L stainless steel.

• Combination nipples are recommended for low-pressure discharge and suction service for compatible liquids. They are not for compressible products such as air or nitrogen on sizes 1¼" and above.

• King Combination Nipples are not recommended for steam.

• The working pressure may vary with the construction of the hose, the type of clamping system used and the application.

• In accordance with the Rubber Manufacturers Association bulletin for oil suction and discharge hose, a coupled length of hose in any size should be tested to 1½ times the working pressure and held for fifteen minutes without leaking or coupling movement. For additional information and detailed instruction on testing procedures, see the RMA handbook.

Loading... Please wait...

Loading... Please wait...